PAPER PACKAGING

Our Paper Packaging offers a canvas of possibilities with food-grade materials and stunning CMYK printing, hot stamping, and embossing/debossing options. Crafted from premium Art Paper and Kraft Paper, each package can be finished with either sleek Gloss or Matte Lamination, or a Spot UV Varnish. This ensures that your product not only catches the eye but also reflects a commitment to sustainability with its recyclable nature.

PRINTING:

FINISHING:

MATERIAL:

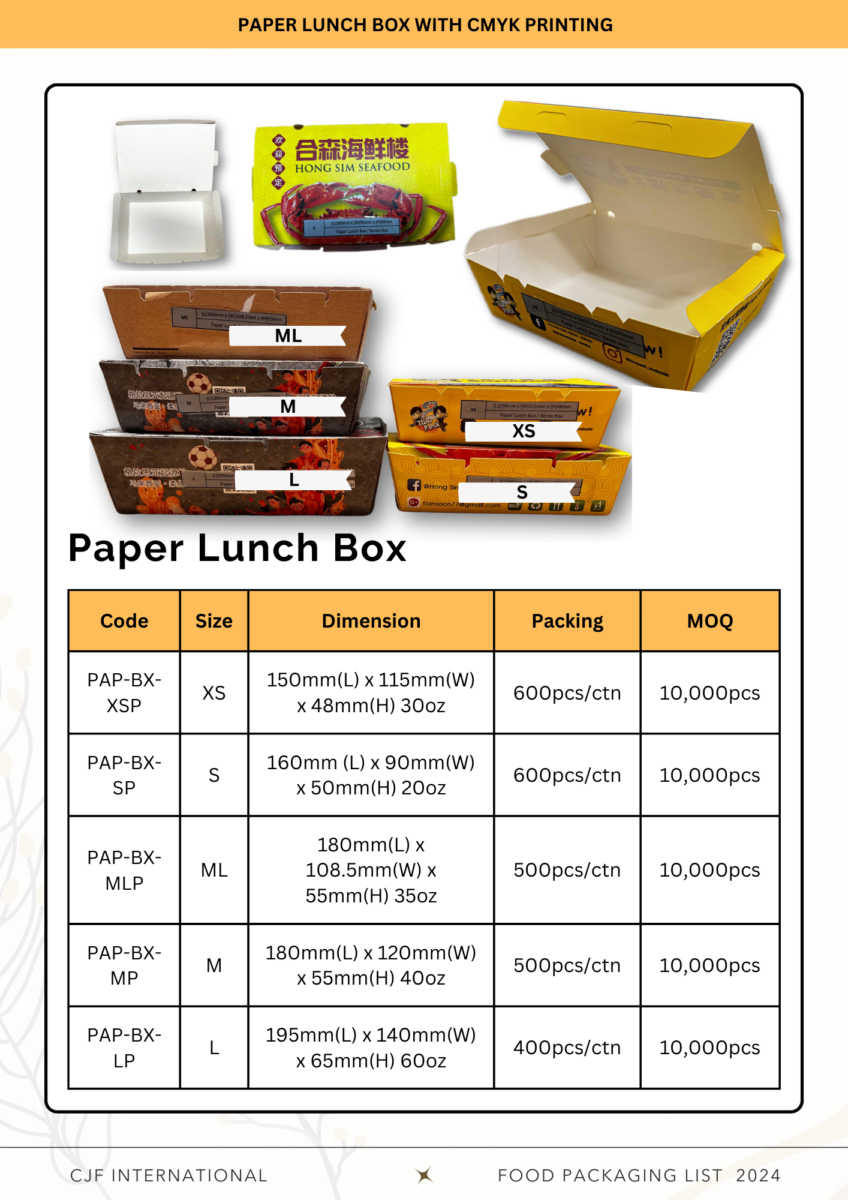

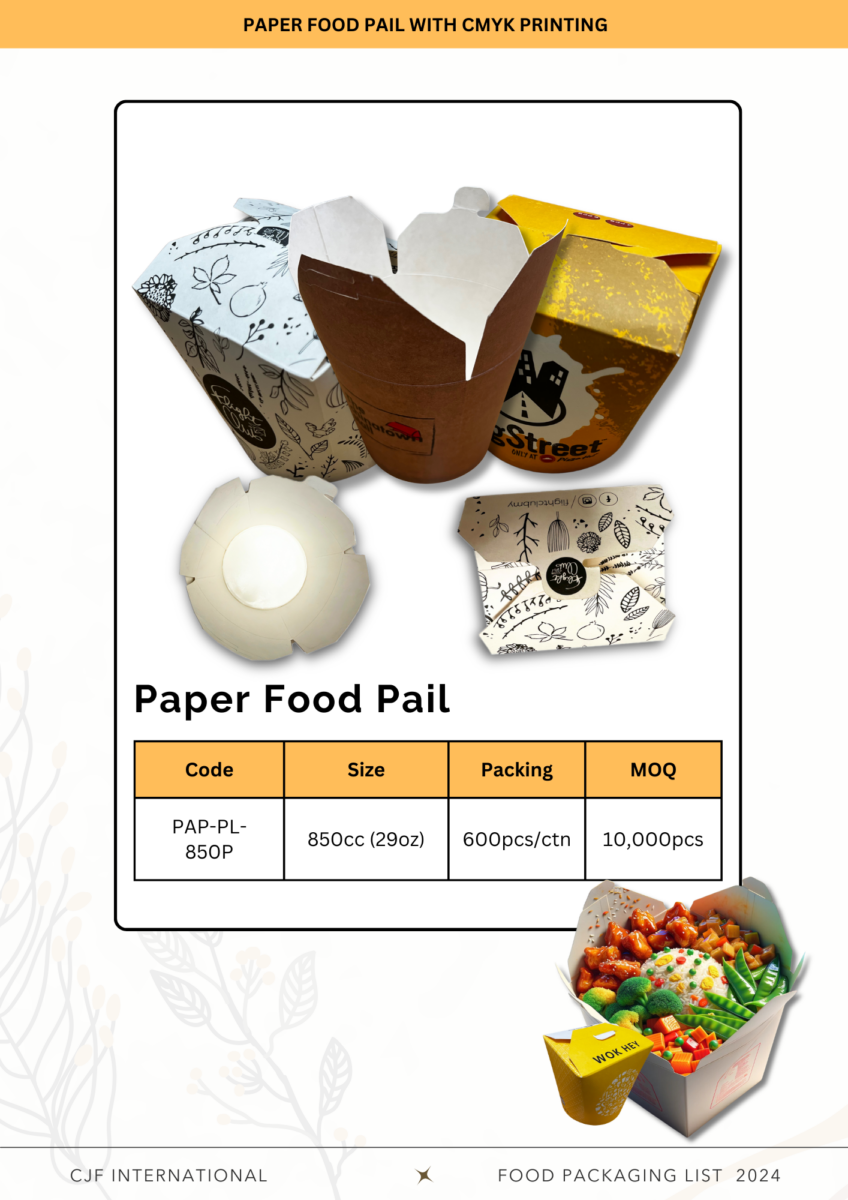

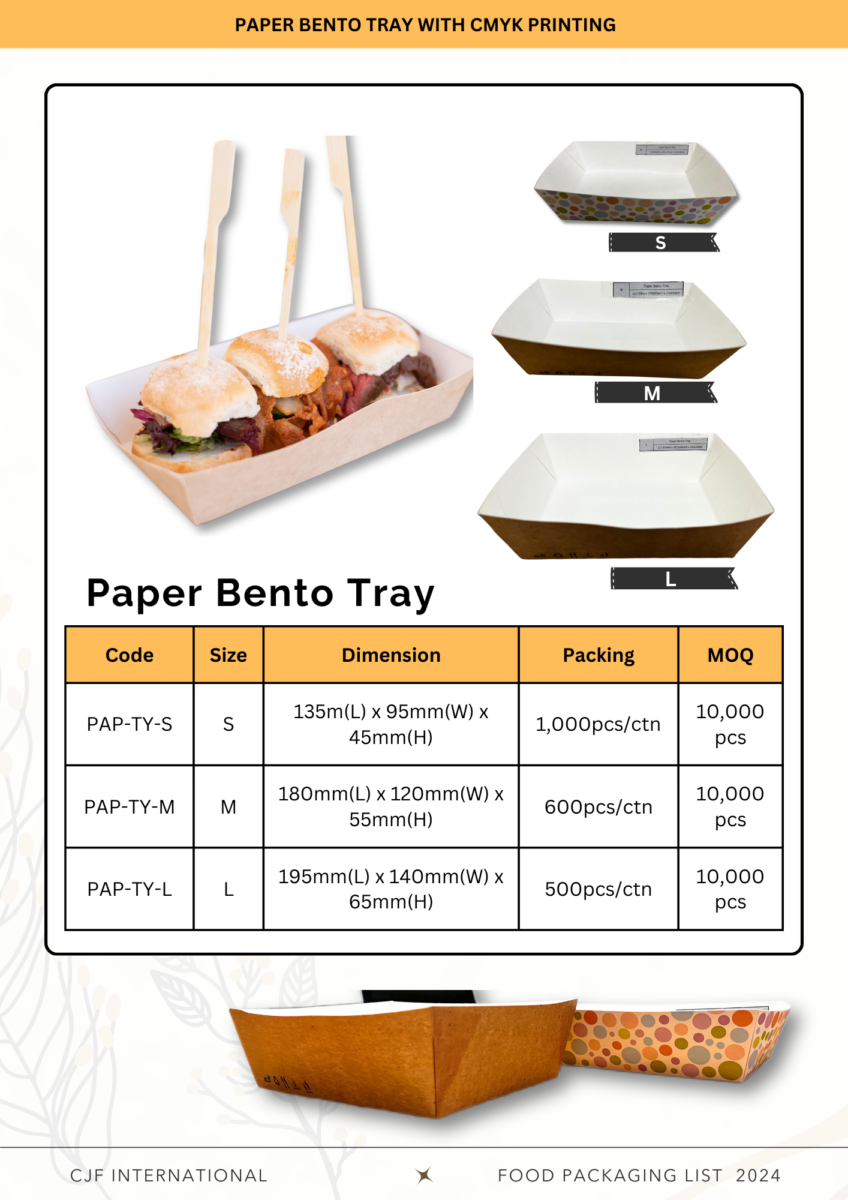

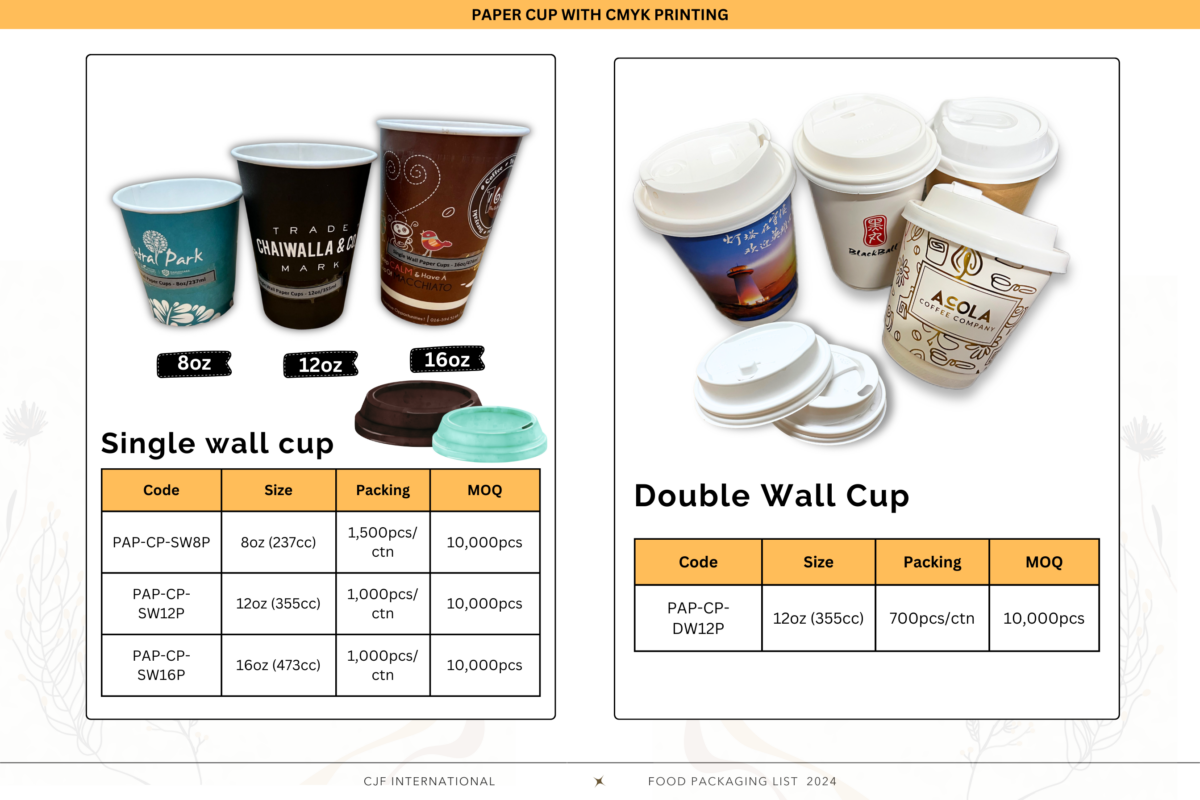

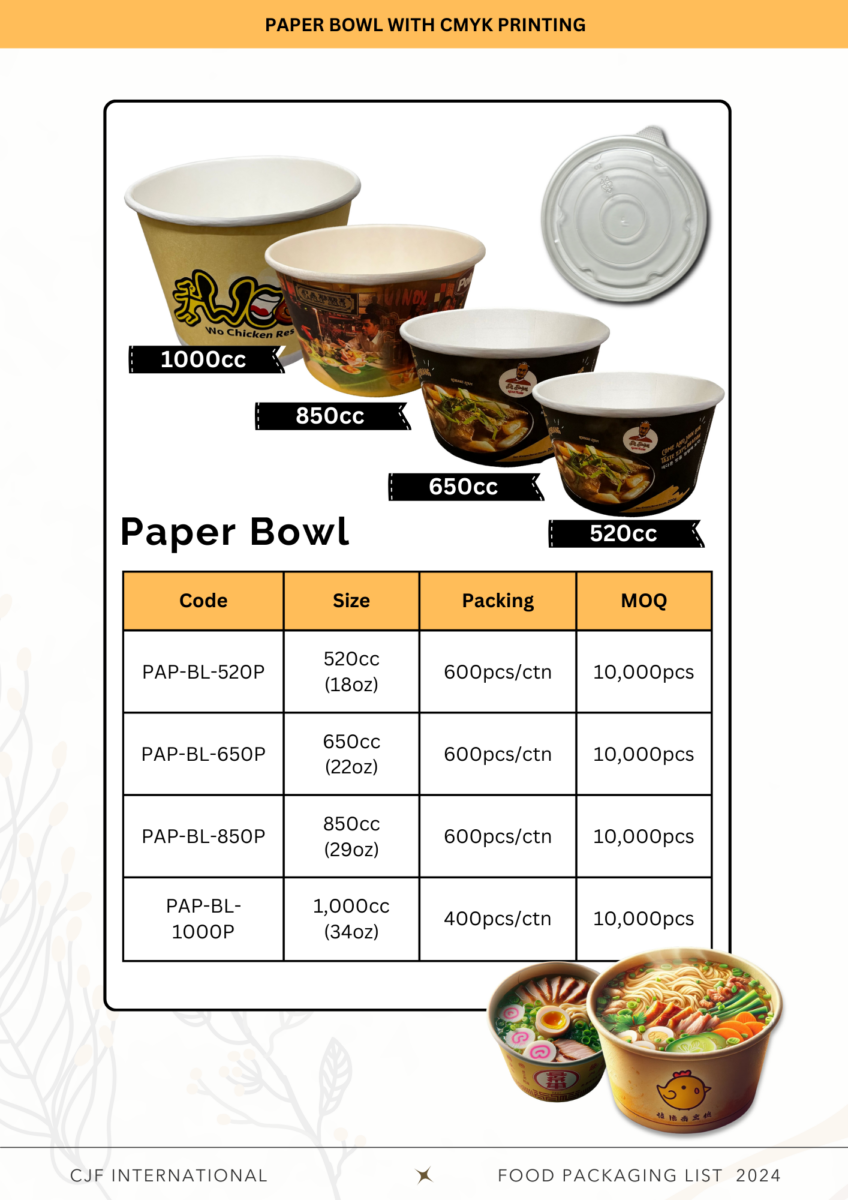

Paper Packaging Catalogue

Difference between embossing and debossing

Embossing and debossing are two distinct techniques used in the food packaging industry to create eye-catching designs and enhance the overall appeal of packaging materials. While they might sound similar, they have unique characteristics that set them apart.

Embossing involves raising the surface of the packaging material to create a three-dimensional effect. This is achieved by using a die or mold that presses against the material from the backside, pushing it outward. The result is a raised design or pattern that adds texture and elegance to your packaging. Embossing is often used to highlight logos, brand names, or decorative elements, giving them a tactile and visually appealing quality.

Debossing, on the other hand, is the opposite of embossing. Instead of raising the design, it involves pressing the design into the material, creating a depressed or indented effect. This technique can also add depth and sophistication to your packaging. Debossing is commonly used for creating subtle and understated designs, conveying a sense of luxury and professionalism.

Choosing between embossing and debossing depends on your packaging goals and the message you want to convey to your customers. Embossing tends to make designs more prominent and attention-grabbing, while debossing imparts a more subtle and sophisticated touch.

Both embossing and debossing can be combined with other printing methods, such as foil stamping or spot UV coating, to further enhance the visual impact of your packaging. Whether you opt for embossing or debossing, these techniques can elevate the perceived value of your products and leave a lasting impression on your customers.

Different Types of Finishing

Gloss Lamination

Imagine your product catching the light as it sits on a shelf, the colors dancing vividly as customers pass by. That's the magic of Gloss Lamination. It's like putting your product in the spotlight, literally. This finish is known for its high-shine, reflective quality that makes colors look more saturated and images appear sharper.

If your brand is all about vibrancy and energy, gloss lamination could be your packaging soulmate. But remember, with great shine comes great visibility of fingerprints – a small trade-off for the brilliance it offers.

Matt Lamination

Matt Lamination is a kind of finish that doesn't scream for attention but subtly demands it. Colors under a matt finish are softer, giving your packaging a warm, approachable feel.

It's perfect for brands that want to convey a sense of luxury and exclusivity without overdoing it. Plus, it's a champion at resisting fingerprints, ensuring your product maintains its pristine appearance.

Spot UV Varnish

Spot UV Varnish applying a clear, shiny coating to specific areas of your packaging. It creates a fascinating contrast, especially when used against a matt background.

Spot UV is a storyteller; it can guide the customer's gaze to the most important elements of your design – be it your logo, a special message, or a unique pattern. It's a way to add depth and texture, making your packaging not just a visual but a tactile experience.